Turbine, rotary piston and diaphragm gas flow meters have traditionally dominated the UK gas metering marketplace, however new digital technologies including Ultrasonic and Thermal Mass flow measurement are challenging this status quo.

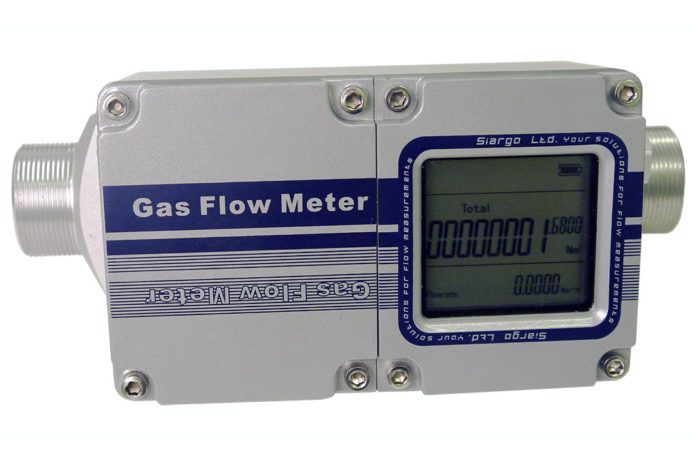

The MFGD Thermal Mass meter, manufactured by Siargo – California, is one such design and incorporates proprietary MEMS sensor intelligence powered by a replaceable three year battery, showing flow rate and total flow displayed on the integrated LCD readout.

The MFGD range offers inherent advantages over existing traditional technologies and is available exclusively in the UK via Bell Flow Systems in Buckingham.

Specially designed for natural gas metering, the MFGD is able to reduce traditional un-corrected accuracy losses caused by temperature and pressure variations as these models compensate electronically for the volumetric expansion of gas using patented, advanced MEMS technology.

There are many advantages to this method of gas flow measurement. This type of sensor features zero moving parts in a nearly unobstructed straight through flow path, which facilitates extremely low pressure drop measurement. Maintenance costs are low, and this type of meter is very sensitive at low flow rates, which allows for a high turn-down ratio whilst remaining accurate over a wide measuring range.

The MFGD models provide a pulse output and RS232 for remote data logging capabilities and BMS integration. This range is constructed of Aluminium with stainless steel options and features BSP threaded connections as standard, available in sizes DN32 to DN80.