This is especially true when a property’s heating system is renovated, and a combi boiler installed, or if the homeowner wants to add more bathrooms or en-suites.

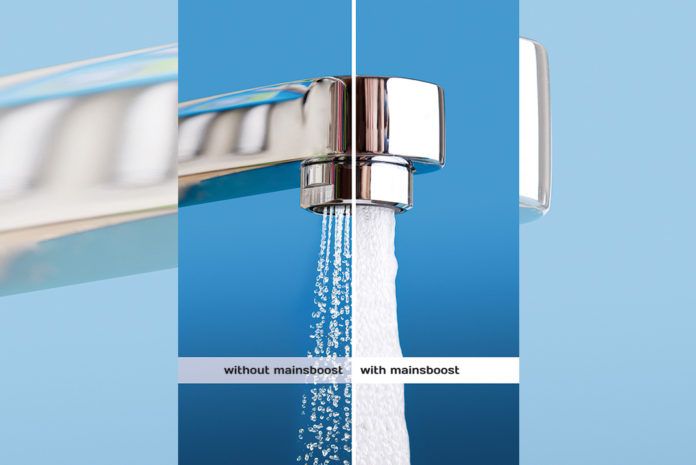

For installers who are called out to fix poor water pressures, one solution is to suggest pressure boosting technology. Fitted directly onto the incoming mains water supply, pressure boosting systems work to increase water pressure to a more acceptable level.

The WRAS-approved Stuart Turner Mainsboost cylinder contains a diaphragm chamber surrounded by positive pre-charged air pressure, which is sealed within the vessel. When mains-pressure water enters the chamber, the diaphragm expands to create a state of equilibrium between the water pressure and the pre-charged pressure. Water is then forced out of the cylinder at this pressure when an outlet is opened, boosting the incoming mains supply and enabling multiple outlets to be fed with no loss in pressure. Once the outlets are shut off, the diaphragm will refill and the pressure reset ready for the next use.

Before replacing an existing vented system with a combi boiler, installers should take the time to discuss the issue of water pressures with the homeowner. It is important to fully explain the impact the switch to a combi boiler may have on the water pressure at their taps and showers and, where necessary, to recommend the installation of a pre-emptive solution such as the Stuart Turner Mainsboost range which can prevent these kinds of problems from occurring in the first place. Not only will this result in happier, more satisfied customers and a lower risk of call backs, it also offers installers a valuable opportunity to upsell and generate an additional revenue stream.