The construction sector suffered the weakest increase in average earnings in 2024 compared to all other industries, according to an analysis by Protrade.

The analysis revealed that the industry experienced a 3% growth in regular pay compared to a 5.6% average. Total pay growth including bonuses in construction was even lower at 1.7% annually, it noted.

As a result, the survey revealed that a third of tradespeople are refraining from purchasing new tools and 13% admit to using tools which aren’t in their peak condition due to cost concerns.

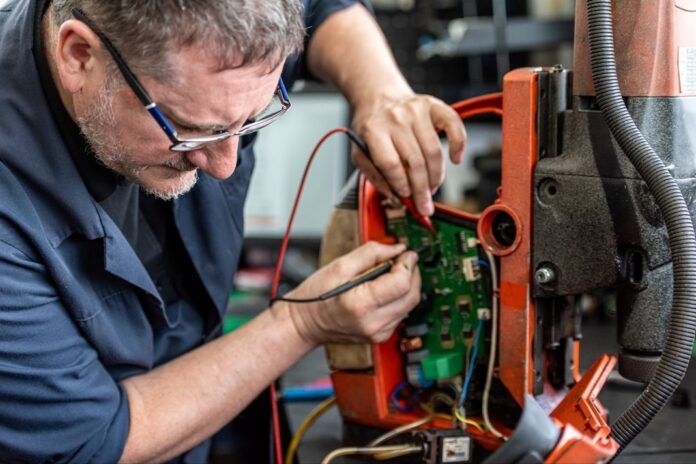

Protrade said it has sought to find a solution by gathering new data to highlight where investing in tool repair can lead to substantial savings for tradespeople.

With the average tradesperson spending £2,592 on new tools every three years, the data revealed that potential savings can be made through the upkeep and repair of professional tools.

According to a statement, tool experts suggested that certain premium tools should be serviced at a qualified tool repair centre at least once a year to ensure they work at optimal levels. If a repair is necessary, it will extend the tool’s lifespan and early diagnosis accompanied with replacement of items like bushings and bearings and can lead to long-term cost savings, it noted.

Based on this, Protrade said it has calculated how many times it is cost-effective to repair a tool before tradespeople are better off buying a new one.

Protrade’s analysis showed that on average, plunge saws, drywall sanders and hammer breakers can be repaired up to five times before they become more cost-efficient to buy a new one. Petrol cut off saws are the next most cost-efficient items to repair, it said, with tradespeople being able to extend the lifespan of this tool through servicing and repairs up to four times before it’s better to buy new.

It further revealed that certain lower value items such as drills, impact drivers and angle grinders simply are not worth repairing.

The average repair costs don’t factor in tool warranties, it cited, which typically provide a standard three-year guarantee on new tools from most manufacturers, covering repair costs during that time, which provides further savings to tradespeople when taken full advantage of.

Craig Sanders, joint managing director at Protrade, said: “Using manufacturer-supplied OEM replacement parts is critically important for safe tool repair. These parts are often only available through authorised repair centres, like our own, and are crucial for ensuring safety. There is a significant danger associated with using non-standard parts and particularly with counterfeit batteries – using these parts can lead to tools catching fire or even exploding due to the absence of essential protection mechanisms.”