A new, cost-effective range of pressure sensors from Sensata Technologies is helping boiler manufacturers and installers working with hydronic heating to avoid variances in liquid pressure that could damage the system or lead to expensive bills for the customer.

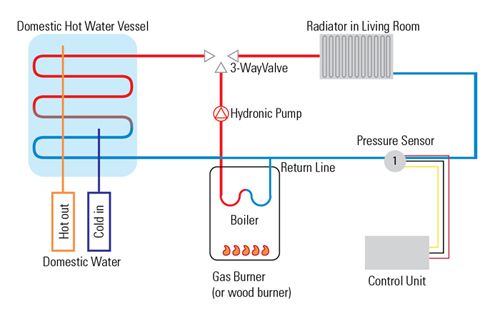

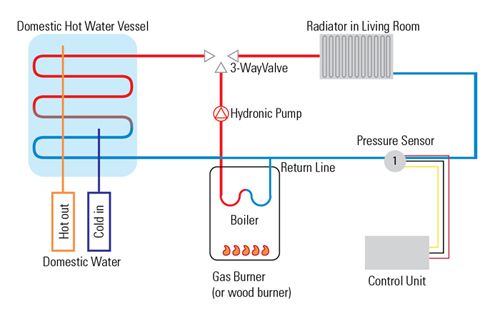

The sensors measure the pressure in the hydronics loop of the central heating boiler. They convert the pressure signal into an electronic (voltage) value which can be acquired by the boiler’s control unit. This is then typically presented on a display and/or thermostat.

Hydronic systems work by transferring heat from the central heating boiler to radiators around the home or office. If the liquid pressure is too high, it can cause leaks or damage to the system; if it is too low, it can damage the heat exchanger inside the boiler.

In either case, an unreliable system is less efficient leading to wasted energy, higher costs and an increase in the maintenance and repair bill. For manufacturers, it is also potentially damaging to the brand in what is an increasingly competitive market.

The two products in the hydronic press measurement range include a 5V dc input model and 6–30V dc input model, both of which are quick and easy to install. The sensors can also be integrated with an App for use on a mobile or tablet to notify the installer (or end-user) of a problem in advance, such as if the boiler needs to be refilled, or a failure is likely to occur. This also helps to support a more effective predictive maintenance regime.